Home / News / Industry News / What are the common surface finishes available for stainless steel stamped parts?

Common surface finishes available for stainless steel stamped parts include:

Matte Finish: The matte finish is characterized by its non-reflective, dull surface. This finish is typically achieved through abrasive blasting or acid etching, resulting in a uniform texture that minimizes glare. The matte finish is suitable for applications where a more subdued, understated look is desired, such as in industrial equipment, outdoor signage, and certain architectural features. It also provides a practical advantage in reducing visual distractions in environments where minimal reflectivity is preferred.

Electropolished Finish: Electropolishing is an electrochemical process that removes a thin layer of material from the stainless steel surface, producing a smooth and shiny finish. This process enhances the metal's corrosion resistance by reducing surface roughness and eliminating contaminants. Electropolished finishes are commonly used in industries that require high levels of cleanliness and hygiene, such as the pharmaceutical, food and beverage, and medical device industries. The smooth surface minimizes the risk of bacterial growth and makes cleaning more effective.

Bead Blasted Finish: The bead blasted finish is achieved by blasting the stainless steel surface with fine glass beads or other abrasive materials. This process creates a uniform, matte texture that reduces reflectivity and provides a visually appealing, slightly roughened surface. Bead blasted finishes are often used in architectural and aesthetic applications, such as building facades, interior design elements, and sculptures. The texture not only enhances the visual appeal but also adds a tactile dimension to the surface.

Passivated Finish: Passivation is a chemical treatment that improves the natural corrosion resistance of stainless steel by removing surface contaminants, such as iron particles, and creating a thin, protective oxide layer. This finish is essential in applications where maintaining the integrity of the stainless steel is critical, such as in medical and food-processing equipment. The passivation process ensures that the stainless steel remains free from rust and other forms of corrosion, extending the lifespan and reliability of the parts.

Satin Finish: The satin finish, similar to the brushed finish but with a smoother texture, provides a soft, satin-like appearance with moderate reflectivity. This finish is created by polishing the surface with fine abrasives, resulting in a consistent, smooth texture. Satin finishes are used in applications where both aesthetic appeal and ease of cleaning are important, such as in consumer appliances, decorative trim, and certain architectural features. The satin finish strikes a balance between reflectivity and subdued elegance.

Etched Finish: Etched finishes involve applying patterns or designs to the stainless steel surface through chemical or laser etching. This process removes material to create decorative or functional patterns. Etched finishes are commonly used in architectural applications, signage, and artistic installations where custom designs and visual impact are desired. The ability to produce intricate patterns and detailed designs makes etched finishes popular in both functional and decorative contexts.

Embossed Finish: The embossed finish involves creating raised or recessed patterns on the surface of the stainless steel through mechanical rolling or pressing techniques. This finish provides both aesthetic appeal and functional benefits, such as improved grip and slip resistance. Embossed finishes are used in applications like elevator flooring, decorative panels, and industrial equipment where texture and visual interest are important. The three-dimensional aspect of the embossed finish adds depth and character to the stainless steel surface.

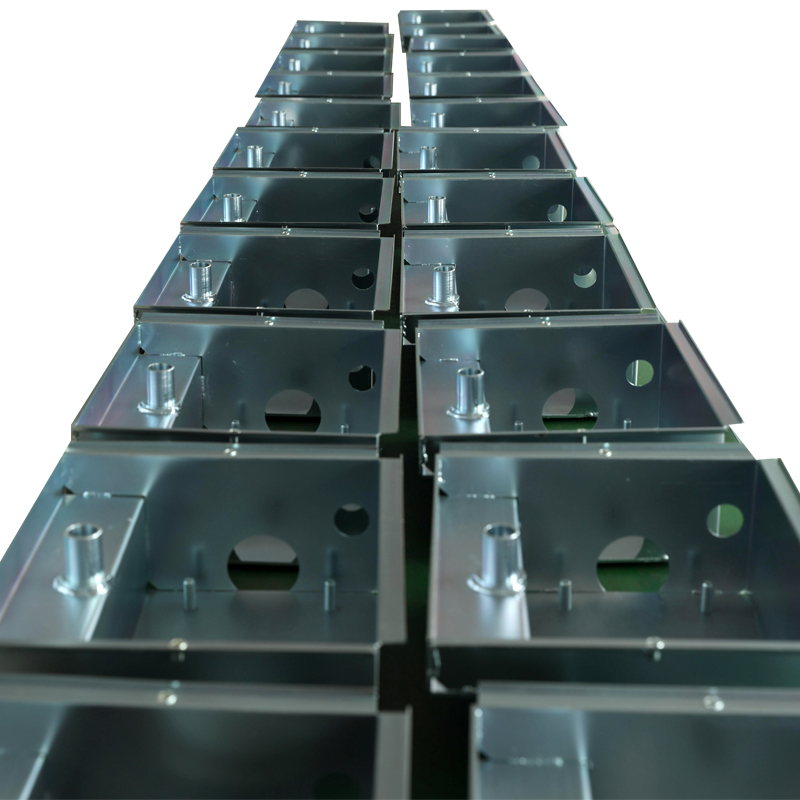

Oem Sheet Metal Processing Bending Punching Manufacturing Process Laser Cutting Stamping Fabrication

English

English 中文简体

中文简体 Español

Español ++86 13567131698

++86 13567131698