Home / News / Industry News / What environmental considerations should be taken into account in metal stamping, especially in terms of waste disposal and energy consumption?

In metal stamping, environmental considerations are crucial to minimizing the industry's ecological footprint. Here are some specific factors related to waste disposal and energy consumption that should be taken into account:

Waste Disposal:

1.Material Recycling:

Metal stamping companies should establish robust material recycling programs that encompass both ferrous and non-ferrous metals. Partnering with specialized recycling facilities ensures that scrap metals generated during the stamping process are efficiently collected, processed, and reintroduced into the production cycle. This not only reduces the demand for virgin raw materials but also minimizes the environmental impact associated with mining and processing ores.

2.Waste Segregation:

Effective waste segregation is paramount to streamline the recycling and disposal process. Implementing a systematic waste segregation system within the facility ensures that different types of waste, including metals, plastics, and paper, are separated at the source. This separation simplifies recycling procedures, making it easier to divert materials away from landfills.

3.Hazardous Waste Management:

Metal stamping often involves the use of lubricants, solvents, and chemicals. Proper management of these hazardous materials is essential to prevent soil and water contamination. Companies should adhere to stringent regulations governing the storage, transportation, and disposal of such materials. Regular training sessions and strict protocols for handling these substances are crucial to maintaining a safe and environmentally responsible workplace.

4.Waste Minimization:

Waste minimization strategies, such as optimizing cutting patterns and adopting precision engineering techniques, can significantly reduce material wastage. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies enable engineers to optimize the layout of parts on metal sheets, minimizing unused areas and consequently reducing scrap generation. Continuous process improvement methodologies, like Lean and Six Sigma, can be applied to identify and eliminate sources of waste throughout the production process.

5.Collaboration with Suppliers:

Collaborative efforts with material suppliers are instrumental in promoting sustainability across the supply chain. Metal stamping companies should engage with suppliers to source materials with high recyclability rates and minimal environmental impact. Additionally, encouraging suppliers to use eco-friendly packaging materials reduces the amount of waste generated during transportation and storage.

Energy Consumption:

1.Energy-efficient Equipment:

Investing in state-of-the-art, energy-efficient stamping machines and equipment is a strategic decision that pays off in the long run. Modern equipment often comes with advanced technologies, such as servo-driven systems and variable frequency drives, which optimize energy usage by adjusting power consumption according to the specific demands of the operation.

2.Lighting and HVAC Systems:

Upgrading traditional lighting systems to energy-efficient LED alternatives significantly reduces electricity consumption. Similarly, HVAC systems should be optimized to maintain comfortable working conditions while minimizing energy usage. Implementing smart HVAC controls, regular maintenance, and insulation improvements contribute to energy conservation efforts within the facility.

3.Process Optimization:

Conducting regular process audits and employing data-driven analysis tools allow companies to identify inefficiencies in the stamping process. By optimizing tooling designs, material usage, and production sequences, cycle times can be reduced, leading to lower energy consumption per unit of output. Continuous monitoring and adjustment of operational parameters are key to achieving sustainable energy practices.

4.Renewable Energy Sources:

To further reduce the carbon footprint, metal stamping facilities can integrate renewable energy sources into their power supply. Solar panels, wind turbines, or other renewable energy technologies can be installed on-site, harnessing natural resources to generate electricity. This diversification of the energy mix decreases reliance on non-renewable sources and contributes to a more sustainable energy infrastructure.

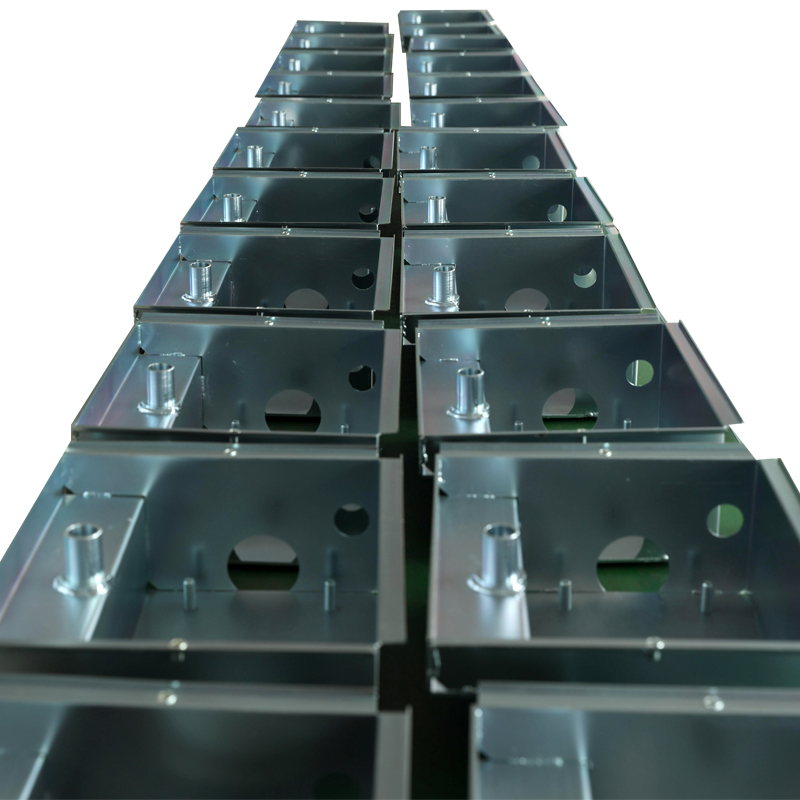

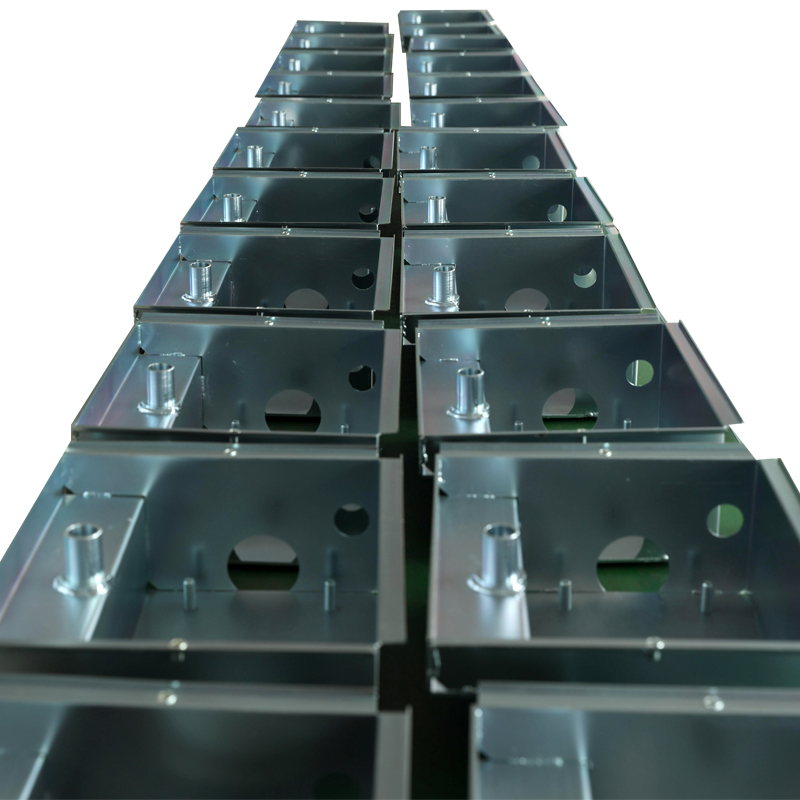

Oem Sheet Metal Processing Bending Punching Manufacturing Process Laser Cutting Stamping Fabrication

Oem Sheet Metal Processing Bending Punching Manufacturing Process Laser Cutting Stamping Fabrication

English

English 中文简体

中文简体 Español

Español ++86 13567131698

++86 13567131698